Breton supplies the aerospace industry with 70% of its machine tool production, covering a wide dimensional range. All machines share the 5 continuous axes configuration. Customer service is the essential ingredient ("Tecnologie Meccaniche", July 2017).

Lightweight airframe, maximum engine power, minimum weight and high safety levels are just a few of the key factors when serving the aerospace industry.

To accomplish these goals, designers need to distinguish between two macro areas: airframes and engines, both of which share the need for extreme weight reduction combined with maximised performance.

Requirements change also depending on whether the work is being performed for the civil segment, with its focus on the absolute safety of the aircraft, or the military segment, with its more performance-oriented agenda.

Airframe designers must therefore create a lightweight product, capable of accepting the maximum possible payload and sufficiently rugged to withstand the dynamic stresses generated in flight.

Conversely, powerplant engineers need to concentrate on designing a system with the maximum possible efficiency, minimising weight and guaranteeing safe operation in all application conditions. Aerospace industry suppliers must also remember that technical excellence must be delivered at a reasonable and competitive construction cost, and hence market price. Aircraft construction costs can be broken down into the macro families of design, raw materials, transformation, and assembly.

Here, we focus more specifically on the stage in which the material is transformed into the finished part required for the subsequent assembly process, because it is in this area that cost-cutting efforts are generally concentrated.

|

| Working area of the Ultrix Evo 1200 |

Because of the high technological expertise and certifications demanded by end customers, the number of companies making the most critical aerospace components is quite small. Transformation plants require continuous improvement to meet the binding, competitive market pricing.

Chip removal remains the most widely employed method with respect to existing new machining technologies. In the vast world of machine tool manufacturers those that are able to supply aerospace market form a restricted elite group: a group of which Breton forms part.

Breton supplies the aerospace industry with 70% of its machine tool production, covering a wide dimensional range. Machines for the production of engine parts offer working volumes from 800mm diameter by 700mm height up to 5000mm diameter by 2000mm height.

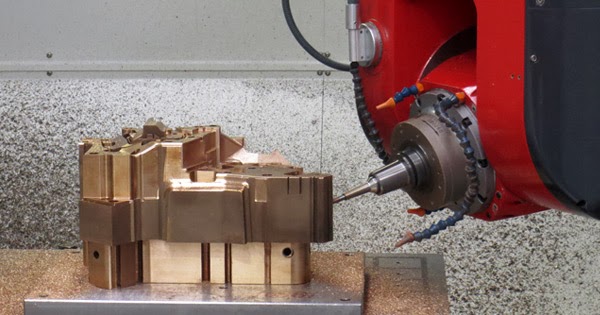

|

| Ultrix Evo working on an aerospace part |

The range of machines for airframe parts offers gantry solutions with working strokes from 2000x2500x800mm to 20000x4500x2000mm.

All machines are configured with 5 continuous axes, and those dedicated to the machining of axially symmetrical parts offer combined turning and grinding functions.

One of the key strengths of Breton's turning solution is that it offers two machines in one, without the compromises typical of lathes converted into milling machines and vice versa. In fact, both the smaller mill/turn solutions, such as the Ultrix, and the large machines like the Maxima, handle lathe work with a dedicated turning bar or with automatic head changeover.

Through this solution, the system can guarantee the performance levels of a dedicated vertical lathe, allowing optimal access also to the inside of components and better control of machining stresses, while preserving valuable electrospindle bearings.

The bearings are another Breton hallmark, because despite their compact size they offer exceptional levels of performance gained through a painstaking co-design process working alongside the main electrospindle manufacturers.

|

| Example of a part made on a Breton machine |

All systems manufactured by Breton are designed to provide high speed machining, with limited material removal depths and high feed rates to ensure the maximum accuracy plus lower levels of residual internal stress in the workpiece. This feature is a perfect fit with the aerospace industry, with its reduced machining allowances and highly distortion-sensitive components.

One of the main features of Breton machines is the guaranteed accuracy of the machining processes. This property is based on careful research into the mechanical perfection of the components and the final assembly, with exclusively thermal expansion caused by ambient conditions being addressed with the use of electronic compensation systems.

And on account of its dynamic spirit, Breton can boast another important characteristic: all standard solutions can be tailored to match the customer's specific requirements without affecting reliability… and at costs that are significantly lower than those associated with ground-up re-engineering.

|

| Heads magazine |

Breton also offers a comprehensive range of automation options for both stand-alone machining centres or systems to be incorporated in an existing production line. The company can supply modular tool changers (from 30 tools to more than 400), pallet changers, part handling automation systems, advanced measurement systems for components and tools, workpiece temperature probes for dimensional offsetting, and far more besides.

Rather than simply supplying a machine to the end customer, thanks to an in-house team of technologists skilled in all the materials used primarily in the aerospace industry, Breton builds a quasi-family relationship with its customers, accompanying them throughout the entire process: from the initial choice of the solution to construction and testing of the first machined parts. So, rather than approaching the market as a supplier, Breton works as a partner able to accompany customers throughout the entire life cycle of each product supplied.

For more information please write to mail@breton.it.

Thank you for the attention and best regards.

Bye-bye

Sergio Prior